Why Ener-G-Block?

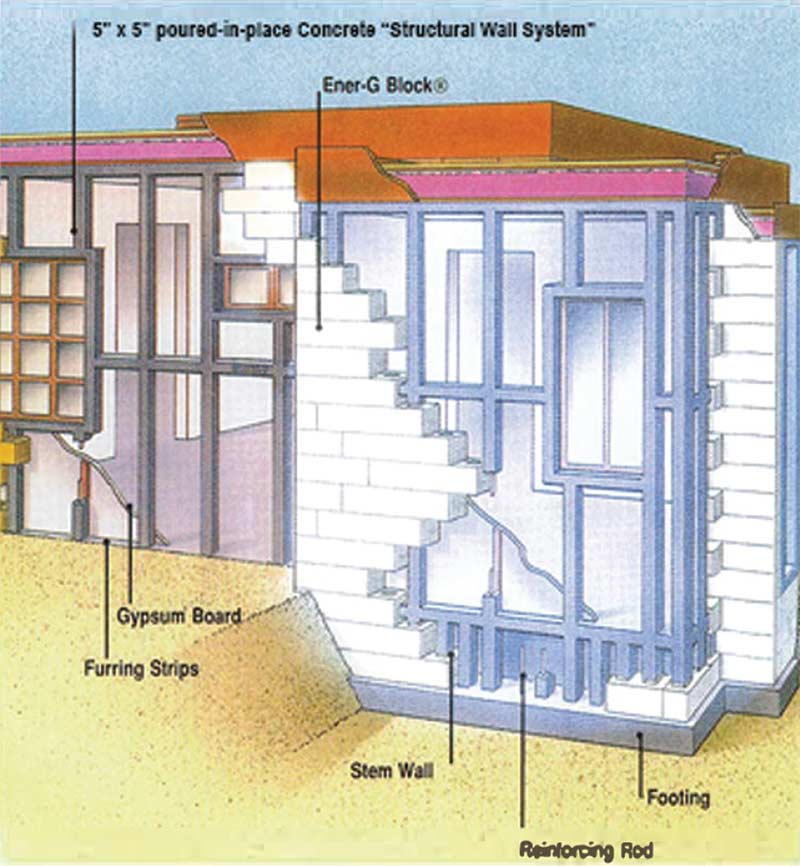

Ener-G-Block is faster. With no added insulation or form work needed, this time-saving 2-block system requires far less labor and results in a stronger, safer, and better insulated structure.

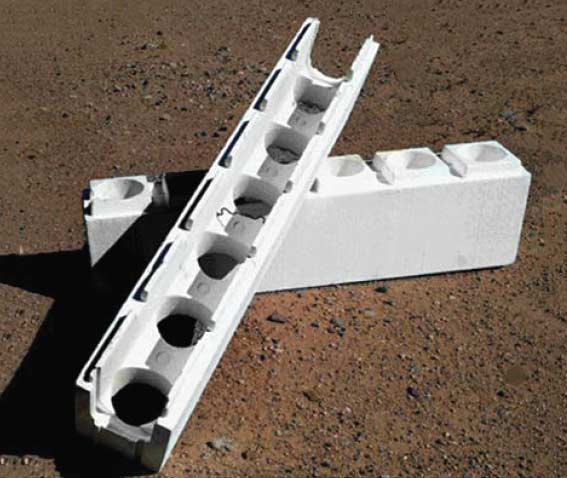

Ener-G-Block uses less than half of the concrete of other ICF systems, and there are only two simple blocks to work with. This means no divider webs; no right, left or corner blocks; and little to no shoring work. And since the process creates the form work within the blocks, no concrete forms or scaffolding are needed, either. EB walls go up 7x faster than CMU walls and are 10x stronger than wood.

- Simple 2-block system

- 7x faster than CMU

- 10x stronger than wood

- R-34 in-wall nominal R-value

- Class-A fire rating

- 50% up-front and ongoing energy savings

The savings don’t end with time and labor. Ener-G-Block saves you on energy and operation costs as well. With built-in insulation, HVAC tonnage can be reduced by 50%, meaning less equipment and lower energy bills for your clients.

Up-Front Financial Benefits

Ener-G-Block walls go up faster, saving tens of thousands of dollars in labor and financing costs.

EB walls require only one system and one crew from the footing to the roofline, which eliminates the need for scheduling multiple trades for the same wall. This means faster build-out times and getting your client’s building occupied sooner than their competitors.

Building with Ener-G-Block can mean immediate tax credits to go along with lower HVAC equipment costs.

Recently passed federal legislation gives owners a one-time $1.80/sq ft tax deduction for commercial buildings that are 50% more efficient*, which could result in thousands in savings for your client on top of the reduced costs on HVAC equipment. This also helps your buildings meet the EPA’s Energy Star criteria and adds value to your projects. Plus, Ener-G-Block can contribute up to 17 of the 26 points needed for LEED certification based on the building design.

Continuing Financial Benefits

The built-in energy efficiency of Ener-G-Block can significantly reduce operating costs.

EB buildings conserve energy and reduce heating and cooling costs by 50% because they only require half of the equipment. The in-wall nominal R-value of R-34 in an EB wall provides over 60% higher wall insulation than a typical 2×6 stick construction wall. This also means that using Ener-G-Block in the stem wall greatly reduces heat transfer in the foundation. To match the total thermal performance of EB construction, a conventionally-built structure would have to reach an R-40 or higher standard. Plus, the EB system creates walls with an uninterrupted, air-tight envelope, with virtually no air infiltration and a reduced the load on the HVAC system.

Ener-G-Block saves your clients money on maintenance and insurance, too.

With a Class-A fire rating, the polystyrene block and concrete core in an EB wall will also resist damage from wind, earthquakes, termites, rot, mold and mildew like no other wall system can. Not only are maintenance and insurance costs greatly reduced, but the safety of building occupants and their businesses is significantly elevated. EnerG-Block structures hold their value for generations.

With a 4-man crew, this 100,000 sqft project will take approximately 6 weeks build-out time with Ener-G-Block vs. 3 months and a crew of 15 with CMU.

Comfort, Health, Safety and Green Benefits

As well as offering significant up-front and ongoing advantages, EB buildings are quieter, more comfortable, safer and environmentally considerate. Because EB walls block about 75% more sound than conventional walls, and because an unbroken exterior envelope results in fewer cold spots and drafts, Ener-G-Block structures provide a quieter and more comfortable interior environment. Plus, the strength and durability of concrete helps protect occupants from crime and natural forces.

There are health advantages as well. Ener-G-Block eliminates manufactured wood products and minimizes harmful exposure to VOCs and off-gassing, and provides mold resistance. Using concrete with fly ash that would otherwise go into landfills, EB walls don’t contribute to deforestation. And increased energy efficiency overall means a smaller carbon footprint and a reduced dependence on foreign oil.

Ener-G-Block is Made in the USA

Up-front and long-term, inside and out Ener-G-Block is the cutting-edge wall system for commercial buildings.

Structures built with Ener-G-Block help lower construction and maintenance costs, protect assets from natural and man-made threats, and increase occupant safety and satisfaction. With Ener-G-Block, beauty, efficiency and comfort are more than skin-deep; they’re built into the core. Whether you’re building a storage facility, hotel, theater, school, warehouse, apartment or office building, or custom home, think Ener-G-Block.